Instructions

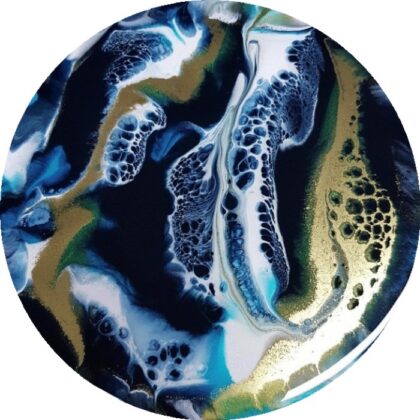

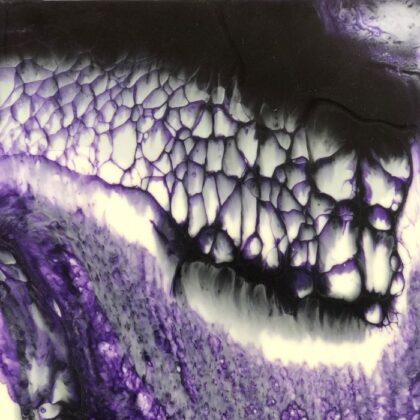

To get you started, we offer the following colorant loading levels. Results may vary.

By Weight Using A Gram Scale: Add Ignite™ colorant at a ratio of between 0.5% – 1.5% of the total weight (Parts A + B mixed) of the material being cast. 1% pigment yields the best results. Adding more than 1.5% by weight offers no benefit and is a waste of the colorant. Too much colorant may cause cure inhibition.

By Volume Measured In Drops: Add 30 drops of Ignite™ per 3 oz (88 ml) of mixed urethane material. If using a translucent material (like Smooth-Cast 325) you can use 15 drops to maintain translucency of the material.

Pre-Mix Before Using: Ignite™ colorants are pigment dispersions and may separate over time. They must be thoroughly pre-mixed in the container before using with a liquid urethane product.

Directions For Use: After dispensing the required amount of urethane material Parts A and B into measuring containers, add colorant to Part B and mix thoroughly. Combine Parts A and B into a mixing container and mix as directed by the urethane product technical bulletin. Blending Colors – You can combine different colors on a pallete to create a custom color before adding to liquid urethane product as directed above. Recommended loading maximum is 1% Ignite pigment by weight.

Smooth-On offers this color guide as a general reference only and assumes no responsibility for color accuracy or matching. Results will vary from one material to another. The end user is solely responsible for determining color suitability and accuracy. Small scale testing is recommended. User determines amount to add; If this is your first time adding color tint or pigment to a urethane, epoxy or silicone system, you may want to test the color effect by adding a few drops to a small amount of urethane material and observe the outcome. It may take a few test castings to attain the desired color outcome.