Jesmonite AC100 is a water-based composite material used to make decorative moulded objects. It is safe to use and contains no solvents or VOCs. It can be cast and laminated using our unique Quadaxial Glass.

Product benefits

- Superior cast and glass reinforced mouldings

- Solvent free & no VOC’s

- Fire resistant

- Lightweight

- Impact resistant

Information

- Easy to use, adaptable material for all moulding applications.

- Suitable for decorative cast objects, mould cases, wall panels.

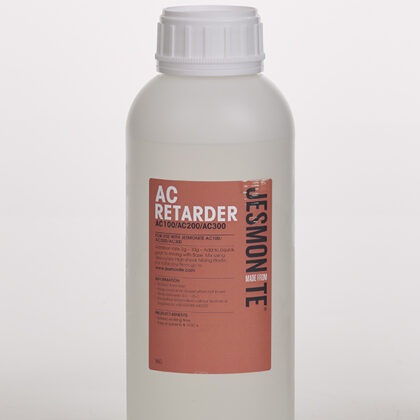

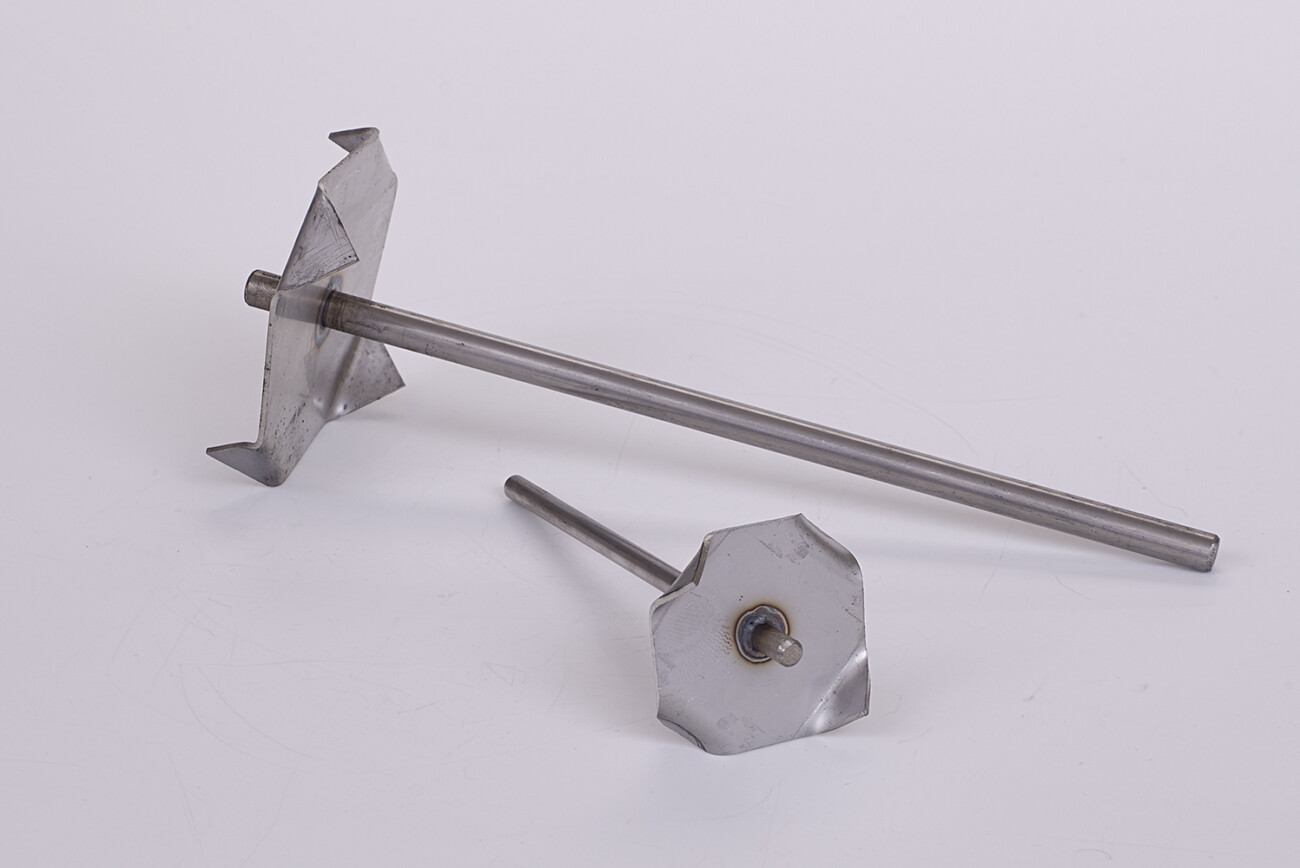

- Supplied with a range of ancillary products including glass reinforcements, pigments, fillers, and control chemicals to adapt the material to the widest range of applications.

- The ultimate chameleon material, can replicate virtually any surface, colour, or texture.

Available in:

Kit sizes range from 3.5kg to 105kg. See the product list for the full range of ancillary materials compatible with AC100.

Packaging change: the powder is now supplied bagged ( no longer in buckets) for the 35kg and bigger kits